Steel Structure Support Systems

Fabricated Structural Steel Support Systems for Colorado’s Extreme Climate

Every structure relies on a strong foundation. Without properly designed and welded steel supports, buildings, bridges, and industrial frameworks risk failure. Whether in the high-altitude regions of the Rocky Mountains or the expanding metro areas of Denver and Colorado Springs, Colorado’s extreme weather—heavy snow, high winds, and occasional seismic activity—demands precision-fabricated structural steel for unmatched durability and safety.

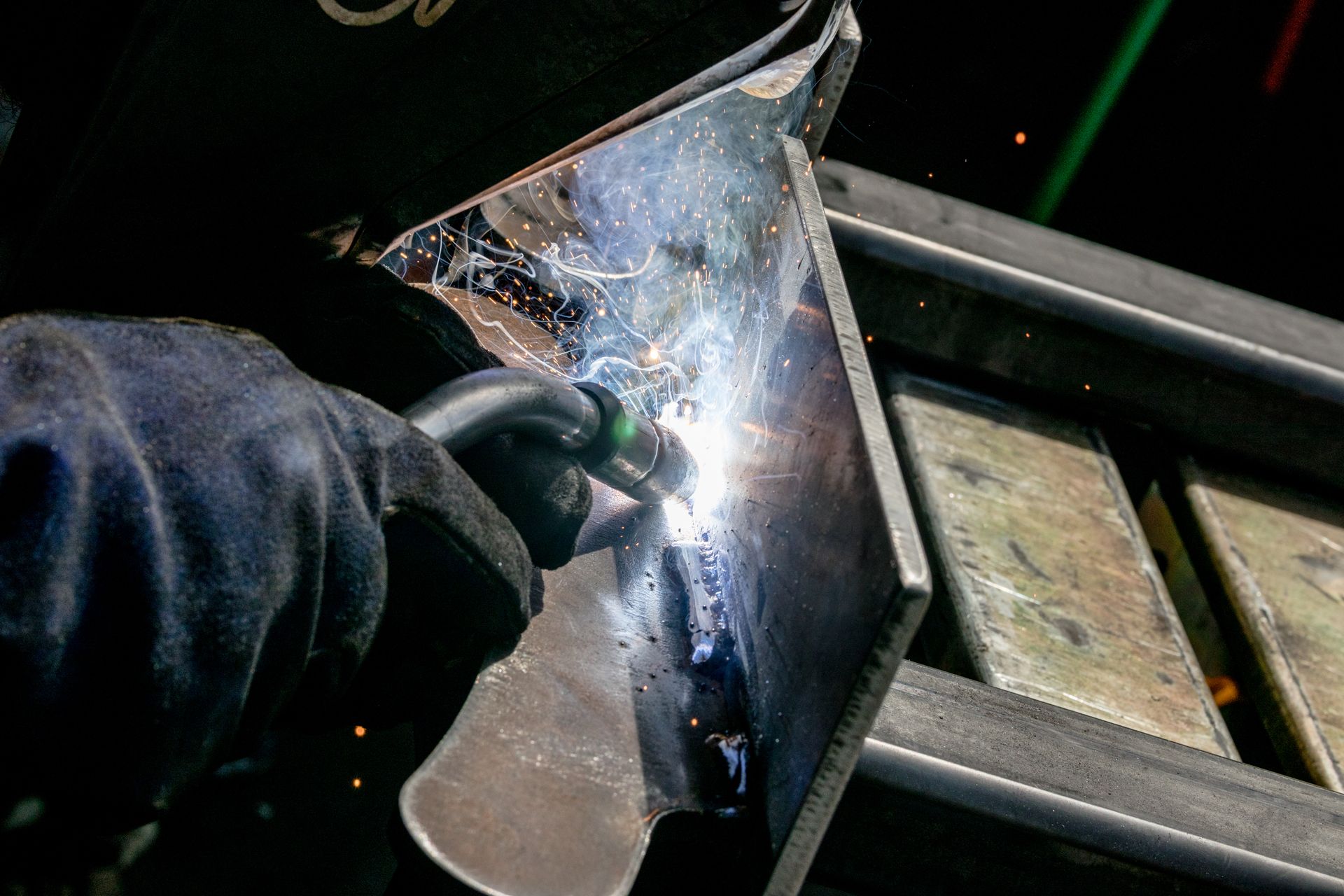

At Top Peak Welding, we specialize in certified structural steel support systems, providing expert fabrication and welding to ensure that your columns, beams, bracing, and load-bearing frameworks meet industry standards and local building codes. Whether you're reinforcing a warehouse in Denver, installing stair towers in Colorado Springs, or securing an industrial platform, our team ensures precision, strength, and compliance.

Understanding Structural Support Systems

Structural steel supports form the backbone of buildings, ensuring stability, durability, and resistance to external forces. These components are categorized into primary and secondary supports.

Elements of Primary Structural Supports

Primary support systems serve as the skeleton of the structure, forming the main framework and transferring loads safely to the foundation.

Steel Columns

- Vertical supports that transfer weight from the roof and upper floors down to the foundation.

- Commonly made from I-beams or H-beams for maximum load-bearing capacity.

I-Beams & H-Beams

- I-Beams are ideal for lighter framing and vertical load support in smaller buildings.

- H-Beams feature a wider flange, distributing weight evenly, making them better suited for high-stress areas, industrial buildings, and regions with heavy snowfall.

Rigid Frames

- Provide clear-span support without interior columns.

- Commonly used in warehouses and industrial buildings to maximize open space.

Components of Secondary Structural Supports

Secondary support systems act like muscles and ligaments, providing reinforcement and additional stability to the primary support.

Bracing Systems

- X-bracing prevents lateral movement and sway, commonly used in high-wind areas.

- Portal Frames maintain structural integrity while allowing for large openings, such as garage doors and windows.

- Moment Frames absorb stress and movement, reducing the risk of structural failure due to wind and seismic forces.

- Seismic Bracing is necessary for earthquake-prone areas, ensuring buildings remain intact during ground movement.

Load Distribution & Reinforcement Components

- Purlins support roof structures, distributing roof loads between primary frames.

- Girts

reinforce walls, preventing buckling and increasing durability.

- Eave Struts connect the roof and walls, ensuring even weight distribution.

- Base Plates anchor columns to the foundation, preventing movement and ensuring structural stability.

Connection Methods (Bolted vs Welded)

When assembling these structural systems, connection methods matter:

- Bolted connections allow fast installation for modular assembly and future modifications.

- Welded connections provide seamless strength, making them the preferred choice for permanent, high-load structures.

Each support type is engineered for specific functions, making fabricated steel a versatile and long term choice for construction projects across various climates. The right combination of primary and secondary supports ensures maximum efficiency and cost-effectiveness, particularly in demanding environments like Colorado, where snow loads and wind resistance are critical considerations.

Built for Colorado’s Toughest Conditions: Precision Steel Fabrication

Structural steel support systems are essential for building stability in Colorado’s high-stress climate. Whether constructing in the foothills of Boulder or the expanding metro areas of Colorado Springs, understanding regional safety codes and environmental risks is key to long-term structural reliability.

Fabricating Structural Systems for Colorado’s Weather

Colorado’s extreme weather makes precision steel fabrication essential for long-term building integrity. Structural steel in Colorado must withstand:

- High Winds: Gusts exceeding 100 mph require reinforced bracing and deep-penetration welds.

- Heavy Snow Loads: Roofs and beams must handle significant weight accumulation without bending or buckling.

- Seismic Activity: Though infrequent, seismic events necessitate seismic-resistant supports to prevent unexpected structural damage.

- Freeze-Thaw Cycles: Temperature swings cause expansion and contraction, increasing stress on joints and welds, which can lead to material failure.

Industry Standards for Structural Support Welding

Every steel-framed structure must meet strict safety codes that protect lives and investments while ensuring long-term strength and reliability. Fabricating and reinforcing structural support systems must comply with:

- AWS D1.1 Structural Welding Code: Governs structural integrity and load-bearing performance of steel support systems.

- ASTM Standards (A36, A572, A588): Define material strength, corrosion resistance, and longevity of steel components.

- Colorado Building Codes (IBC & OSHA): Ensure structural steel supports meet seismic, wind, and load requirements for large-scale construction.

Importance of Proper Structural Fabrication

Without properly fabricated metal supports, buildings face:

- Load-Bearing Failures: Weak connections compromise structural integrity, increasing the risk of collapse.

- Cracking & Deterioration: Stress points caused by improper fabrication lead to fractures over time.

- Safety Hazards: Poorly designed supports pose risks in high-load environments, endangering entire structures and lives.

By combining certified welders, industry-standard compliance, and local expertise, Top Peak Welding delivers fabricated steel structures built to withstand Colorado’s unique conditions with strength and reliability. Contact us today to discuss how our expertise can support your project.

Why Choose Fabricated Structural Steel for Colorado Springs

When compared to other construction materials, fabricated structural steel offers superior durability, efficiency, and long-term cost savings.

Customized Solutions for Strength & Longevity

- Precision-Fabricated Steel: Every metal support system is engineered to withstand Colorado’s extreme climate.

- Minimized Stress Points: Pre-engineered connections prevent premature failures and structural weaknesses.

- Enhanced Longevity: Precision welding techniques increase the lifespan of beams, columns, and bracing systems.

Affordable Fabrication & Maintenance

- Minimizing Material Waste: Efficient metal cutting and assembly reduces unnecessary costs.

- Cost-Effective Solutions: Custom fabrication ensures you get only what you need—no wasted materials or labor.

- Offering Modular and Prefabricated Options: Fast and easy installation with reduced on-site labor costs.

Flexible & Quick Fabrication Work

- Custom Steel Components: Fit complex architectural and engineering designs.

- Modular Fabrication: Allows for easy expansions or modifications.

- Bolted & Welded Connections: Ensure long-term stability while offering adaptability.

Why Choose Top Peak Welding for Structural Steel Support?

At Top Peak Welding, we work with fabricated structural steel, built by certified welders who understand Colorado’s toughest conditions. Our expert engineering and advanced welding techniques ensure strength, durability, and compliance for commercial, industrial, and municipal projects across the state.

With a proven track record in delivering custom-engineered solutions, we maximize structural integrity and efficiency, ensuring every project meets the highest standards.

Build with confidence. Contact Top Peak Welding today for expert steel fabrication designed to withstand Colorado’s toughest conditions—on time, on budget, and built to last.

Top Peak Welding

Business Hours

- Mon - Fri

- -

- Saturday

- -

- Sunday

- Closed